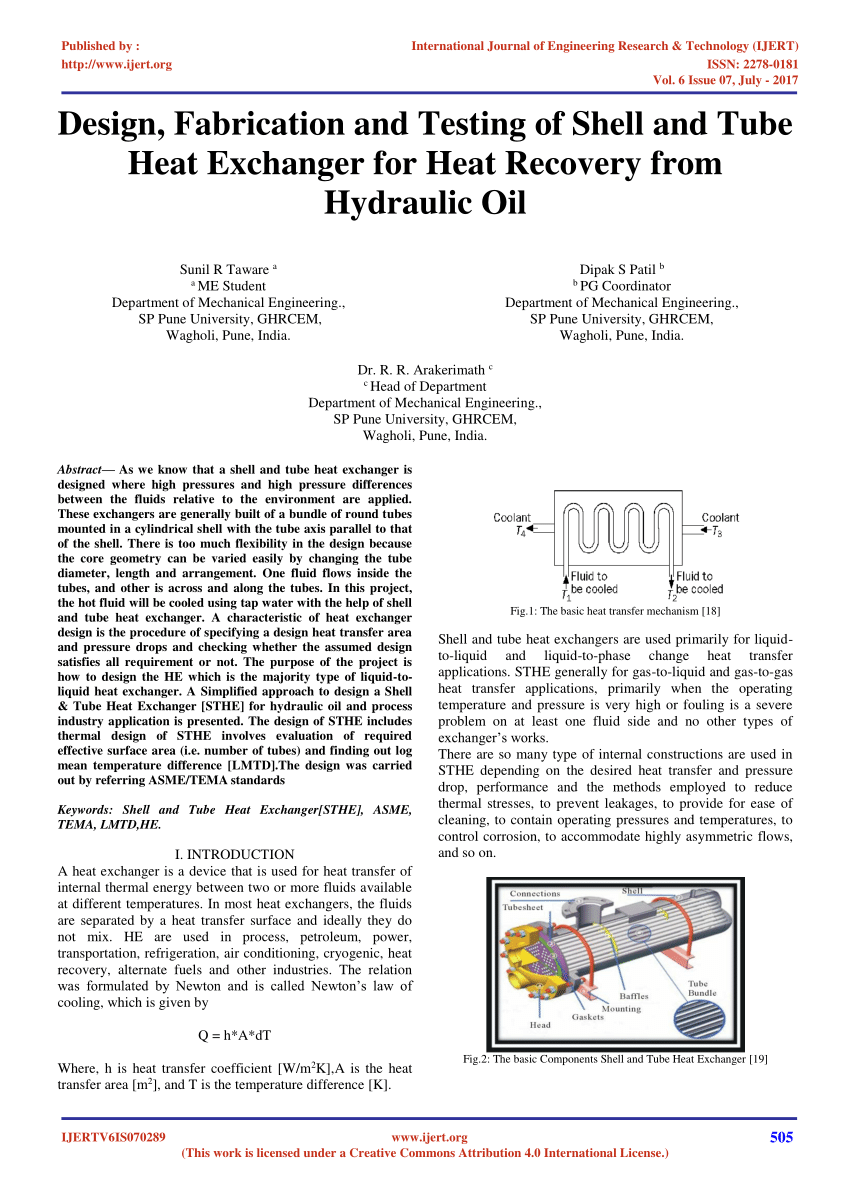

Design of Shell-And-Tube Heat ExchangersProceedings of the Fifth Ocean Thermal Energy Conversion Conference February 20-22 1978 Miami Beach FloridaFundamentals of Diesel Engines - US. Heat Exchanger Fundamentals Most shell-and-tube heat exchangers have multiple passes to enhance the heat transfer.

Heat Exchanger Design Handbook 2nd Ed 1

The tube thickness should be enough to withstand the internal pressure along with the adequate corrosion allowance.

. Using this estimate calculate the heat transfer area. Process fluid assignments to shell side or tube side. For the overall heat transfer coefficient.

22 Full PDFs related to this paper. Due to the high heat transfer efficiency of the plates plate type heat exchangers are usually very small when compared to a tube and shell type heat exchanger with the same heat transfer capacity. Download Full PDF Package.

Mechanical engineers do extensive work on exchanger design to fully specify the exchanger eg. Ft ¼ 00035 þ Ret P 2100 ð4Þ Re042 t The shell side pressure drop DPs includes the pressure loss of the pure transverse flow in the zone between the tops of the baffles. 211 Question for designproblem statement.

Hemisphere Publishing Corporation 1983. Handbook Second EditionHeat Exchanger Design Handbook. This will give you an idea of the approximate size of the heat exchanger and therefore its cost.

Applications of Heat Exchangers Lecture 29. 28 Full PDFs related to this paper. Example 52 Miniature Shell-and-Tube Heat Exchanger A miniature shell-and-tube heat exchanger is designed to cool engine oil in an engine with the engine coolant 50 ethylene glycol.

As its name implies this type of heat exchanger consists of a shell a large vessel with a bundle of tubes inside it. To do this once the number of tubes is. Heat Exchanger Design Handbook Kuppan Thulukkanam This comprehensive reference covers all the important aspects of heat exchangers HEs.

Shell and tube though there are many variants of this design. 1 4 Air-Cooled Heat Exchangers 1611 5215 Compact Heat Exchangers 1611 5216 Boiler Feedwater Heaters 1613 5217. The most efficient condition for heat transfer is to have the maximum number of tubes in the shell to increase turbulence.

College Station Texas 521 HEAT EXCHANGER TYPES AND CONSTRUCTION 1607 5211 Shell and Tube Heat Exchangers 1607 5212 Plate-Type Heat Exchangers 1610 5213 Spiral Plate Heat Exchangers 1610 52. This is due to the larger area the plates provide over tubes. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can be summarised as follows.

Be careful to explicitly state who if anyone will provide thermal or hydraulic guarantee. A short summary of this paper. The vendor receives the design develops drawings and builds the exchanger.

11 Don Green and Robert Perry Perrys Chemical Engineers Handbook Eighth Edition 8th ed. Design and modes of operation and practical large-scale applications in process power petroleum transport air conditioning refrigeration cryogenics heat recovery energy and other industries. 4214 Tube-Side Heat Transfer Coefficient The heat transfer coefficient for the tube-side is expressed as follows.

Selection of stream temperature specifications. 44 and 46 k is the thermal conductivity of the tube-side fluid and is the tube inside diameter. For typical shell-and-tube heat exchangers in a chemical process or a refinery Tables 11-3 and 114 -can be used as a starting point for the estimate.

Fluid Engine Oil Sea Water Inlet Temperature C 65 20 Outlet Temperature C 55 25 Heat Load kW 1179. Here is an example of a 1-2 1 shell pass and 2 tube passes heat exchanger. As you can see in a 12 heat exchanger the tube- -side fluid flows the entire.

Full PDF Package Download Full PDF Package. Design a double pipe heat exchanger with bare inner multi-tubes that can be used to cool engine oil with cold sea water. As you can see in a 12 heat exchanger the tube- -side fluid flows the entire length of the shell turns around and flows all.

The engine oil at a flow rate of 023 kgs enters the exchanger at 120C and leaves at 115C. Setting shell side and tube side pressure drop design limits. 10 Ernst Schl nder et al eds Heat Exchanger Design Handbook Washington.

Heat Transfer Research Inc. Setting shell side and tube side pressure drop design limits. Plate fin heat exchanger.

Here is an example of a 1-2 1 shell pass and 2 tube passes heat exchanger. Contents VIII 1426 FoulingTendencies 32 1427 Typesand Phases ofFluids 32 1428 MaintenanceInspection CleaningRepairand ExtensionAspects 32 1429 OverallEconomy 32 14210 Fabrication Techniques 33 14211 ChoiceofUnitTypefor IntendedApplications 33 15 RequirementsofHeatExchangers 34 References 34 SuggestedReadings 35 Bibliography 35. Tube Tube OD of ¾ and 1 are very common to design a compact heat exchanger.

The corroded tubes is given by Saunders 20 as range of variation of these parameters is based on recommended 0264 values of heat exchanger design handbook 19. Full PDF Package Download Full PDF Package. The 50 ethylene glycol at a rate of 047 kgs enters at 90C.

Most shell-and-tube heat exchangers have multiple passes to enhance the heat transfer. Process fluid assignments to shell side or tube side. Heat Exchanger Design Handbook.

It is the most common type of heat exchanger in oil refineries and other large chemical processes. Determine the shell size. If necessary adjust the number of tube passes to get the velocity to fall in this range.

Tubes baffles shell size tie rods sealing strips skid bars etc. Single Pipe Shell and tube Heat Exchanger Design in Ansys Workbench Designer Modeler Part 1 Lecture 02. DESIGN OF A SHELL AND 2-TUBE HEAT EXCHANGER.

A short summary of this paper. 29 Full PDFs related to. Process Design for the Production of Ethylene from Ethanol.

A short summary of this paper. Water at the r ate of 3000 lbmhr is heated from. You can learn more about tubes and the tube-side construction from pages 11- 40 to 11-41.

A Plat and frame exchanger8 9b Shell and tube exchanger. Sized tube and shell heat exchanger is capable of transferring much more heat. 100 to 130F in a shell and tube heat exchanger.

File Type PDF 5 1 Shell And Tube Heat Exchangers Homepages. Selection of stream temperature specifications. Full PDF Package Download Full PDF Package.

SHELL AND TUBE HEAT EXCHANGER A Shell and tube heat exchanger is a class of heat exchanger. HEAT EXCHANGER DESIGN HANDBOOK-Heat exchanger theory-Ernst U. K 47 i t t t d h Nu where is the Nusselt number for the tube-side fluid which is found by using Eqs.

The following are the design specification. The optimum thermal design of a shell and tube heat exchanger involves the consideration of many interacting design parameters which can be summarised as follows. Heat Exchanger Design Examplea Objective.

Pdf Design Fabrication And Testing Of Shell And Tube Heat Exchanger For Heat Recovery From Hydraulic Oil

Mechanical Design Of Heat Exchangers

Heat Exchanger Design Handbook Heat Exchanger Theory Ernst U Schltinder Yanaki Petkov Academia Edu

Pdf Heat Exchanger Design Handbook Matt Pennington Academia Edu

Pdf How To Design A Shell And Tube Heat Exchanger Mustafa M Al Sarai Academia Edu

Basics Of Shell And Tube Heat Exchangers With Pdf What Is Piping

Heat Exchanger Design Guide By Manfred Nitsche Raji Olayiwola Gbadamosi Ebook Scribd

0 comments

Post a Comment